In recent years, the popularity of electric vehicles has grown exponentially. They not only represent another ecological and sustainable alternative compared to internal combustion vehicles, but they also afford significant advantages in terms of energy efficiency and operating costs.

A key aspect that sets electric vehicles apart is the type of motor they use. Would you like to know more about the different types of electric motors there are and how they influence vehicle performance? We’ll explain them to you!

Battery Electric Vehicles (BEV)

Battery Electric Vehicles (BEV) dominate the market in terms of urban transport. They are zero-emission vehicles used for both passenger and cargo transportation. They are designed to convert electrical energy into mechanical energy using magnetic fields in the motor coils.

Depending on the type of current applied, direct current (DC) and alternating current (AC) motors are distinguished between.

Thanks to technological advances, the autonomy and the charging speeds of these vehicles have improved considerably, also making them ideal for intercity transport.

AC motor

AC motors convert alternating current into mechanical energy. They are the ones used most on the market, especially synchronous motors, due to their ease of use and easy installation, resulting in a longer working life. Under this category we find:

Induction or asynchronous motors

These motors use electromagnetic induction to transform electrical energy into mechanical energy. The magnetic field in asynchronous motors is slightly advanced with respect to the rotor, which allows great speed control, higher performance and overload resistance.

They are ideal for vehicles that seek to reduce noise and vibrations, with high efficiency and reliability. Depending on the construction of the rotor, they can be classified into:

- Squirrel-cage rotor.

- Wound or slip ring rotor.

According to their phases, induction motors are classified as:

- Single phase induction motor: transforms the electrical energy of a phase into mechanical energy.

- Three phase induction motor: converts three-phase electrical energy into mechanical energy.

Synchronous motors

In synchronous motors, the rotor and the magnetic field rotate at the same speed synchronously. Under this category we find:

- Switched or variable synchronous reluctance motor: these motors have a rotor with metal parts where current is generated through the coils. They are economical, they generate less vibrations and they are efficient and reliable.

- Permanent magnet synchronous motor: depending on the position of the induction magnetic field, they are classified as radial flow and axial flow. They are frequently used in hybrid vehicles, they are silent and robust, do not require maintenance, and are very efficient at low revolutions.

DC motor

Direct current motors, although less used today, convert DC electrical energy into mechanical energy through rotary motion. DC charging systems are larger and more expensive, but they allow for faster charging.

Operation of an electric motor

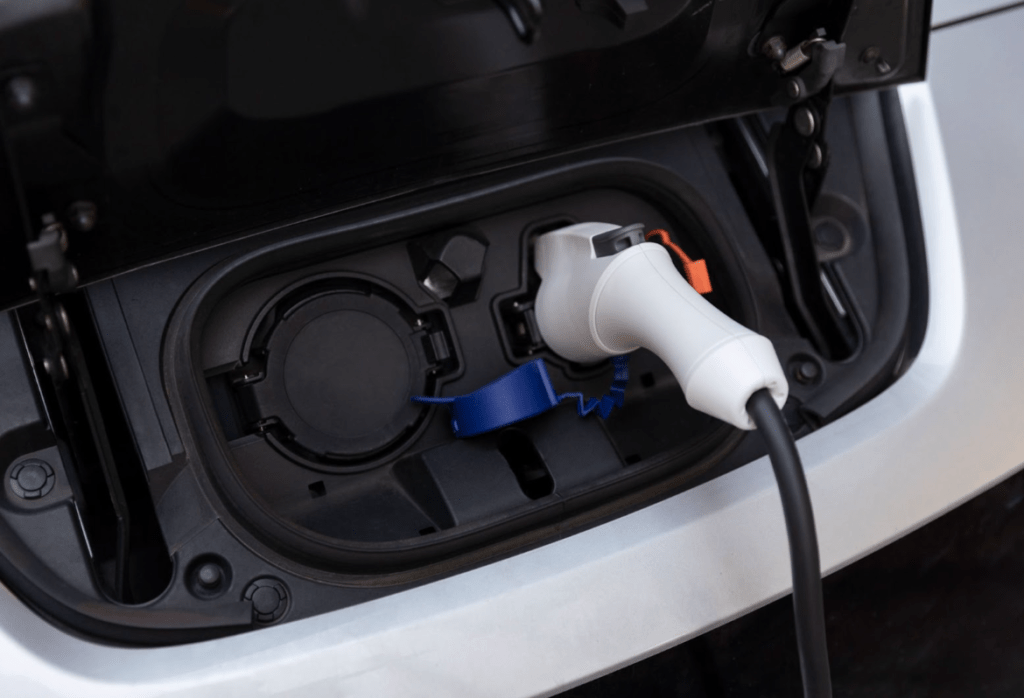

An electric vehicle is charged by connecting it to an outlet, allowing energy to be stored in the battery. Charging may be slow, semi-fast or fast. When accelerating, the battery transforms electrical energy into mechanical energy, providing power to the motor and creating motion.

When decelerating or braking, the electrical system stops sending energy and the vehicle moves due to the inertia of the wheels. In the case of regenerative motors, during deceleration or braking, the vehicle stops using energy and starts generating it again.

So, the different types of electric motors offer a wide variety of options and advantages for electric vehicles, contributing to their efficiency, reliability and sustainability.