Logistical efficiency is a crucial aspect for any company that transports and handles goods. However, this efficiency is not limited only to the performance of the vehicle that moves them from one location to another, contrary to that which is usually thought, but rather it encompasses the entire logistics process, with a particular emphasis on loading and unloading operations. Whilst the former involves putting goods on a means of transport from a point of origin, the latter involves removing them at their destination.

Loading and unloading is not only a critical point on the supply chain, but it is also a key opportunity to improve productivity, cut operating costs and minimise the environmental impact of any company’s activity.

Numerous factors converge in loading and unloading operations, from the efficient organisation of loading to the optimal use of the space available in the vehicle. And speed and precision in this activity not only guarantees the integrity of the transported products, but it also influences the punctuality of deliveries and end customer satisfaction.

So, what are the key strategies for effective loading and unloading in the commercial area? Keep reading!

Pre-loading planning

Even before loading the products into the van, detailed planning is essential. This means taking into account the nature of the load, its weight, volume and fragility. Furthermore, it is essential to organise products so that the time necessary for loading and unloading is minimised.

Use of equipment and technology

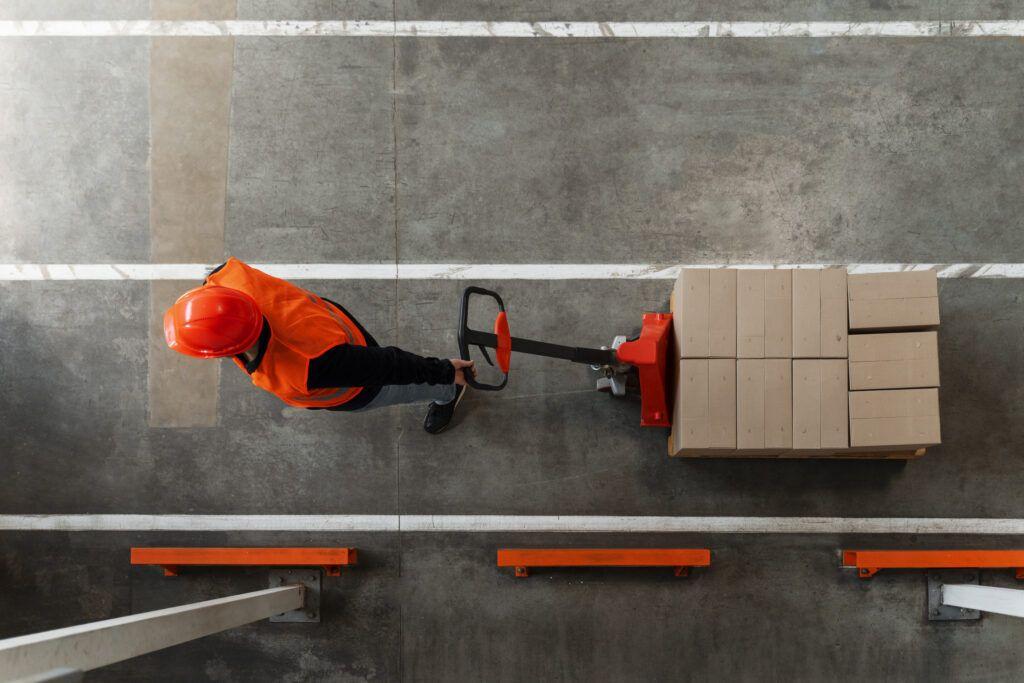

Using the right equipment can make a big difference to the efficiency of the process. For example, having forklifts and pallet trucks can speed up the loading of heavy goods.

Today, there are many 100% sustainable loading and unloading alternatives. In this way, any company that follows an emissions-free policy in its mobility can extend it to other stages of the logistics process, such as loading and unloading. Electric forklifts are increasingly used not only because of their sustainability, but also because of their performance, low cost and versatility.

On the other hand, electric pallet trucks speed up the loading and unloading of vans, reducing physical effort and increasing logistics efficiency. Their compact design and electric operation make them indispensable tools in charging environments.

Use of efficient loading techniques

There are several techniques that can be used to efficiently load a commercial van. One of them is the zone loading method, whereby products are grouped according to their final destination. This facilitates orderly unloading once the van reaches its destination.

Another technique is puzzle loading, whereby products are adjusted so that they take up as little space as possible, thus avoiding wasted space and reducing the risk of damage during transport.

Safety in loading and unloading

Safety should always be a priority when loading and unloading commercial vans. It is vital to train staff in proper cargo handling and provide the protective equipment required to avoid injuries. In addition, the safety regulations and protocols established by the relevant authorities must be followed.

Monitoring and continuous improvement

Once loading and unloading operations have been completed, it is important to monitor and analyse the processes. This allows the identification of possible areas for improvement and optimisation. Feedback from drivers, warehouse staff and customers can be invaluable for implementing positive changes in the future.

Finally, commercial van loading and unloading strategies are essential to ensure an efficient, profitable supply chain. From pre-planning to the implementation of efficient loading technologies and techniques, each step in the process plays a crucial role in the overall success of the logistics operation. By prioritising the optimisation of these operations, companies will improve their competitiveness, cut costs and offer exceptional service.